Audi just released more details on the upcoming 95 kilowatt-hour Audi e-tron battery and its looking remarkably similar to the design of the Jaguar I-PACE pack. Aside from the capitalization of the vehicle names, what’s different and what’s similar?

Both packs contain 36 aluminum “shoebox” modules containing 12 “pouch” cells each for a total of 432 cells. Although Audi didn’t specifically say so, there is little doubt that both cars use 4 cells in parallel in a group for a total of 108 cell groups. Most previous electric cars tended use around 96 cell groups.

Both packs contain 36 aluminum “shoebox” modules containing 12 “pouch” cells each for a total of 432 cells. Although Audi didn’t specifically say so, there is little doubt that both cars use 4 cells in parallel in a group for a total of 108 cell groups. Most previous electric cars tended use around 96 cell groups.

The I-PACE battery pack and it’s 36 modules are visible in this image from Jaguar.

These 108 cell groups are strung together in series which effectively adds up their voltage into a full nominal pack voltage of around 390V since each cell group has a nominal voltage of about 3.6 volts. Battery voltages slump down when near empty and rise up when near full. A fully charged pack with 108 cell groups is likely going to be around 450 volts (Jaguar’s tops up at just under 450V).

The individual cells appear to be physically similar. Audi says their cells hold 60 Ah (a measure of energy holding capacity) vs the Jaguar’s 58 Ah which accounts for the overall capacity difference of “95” kWh vs “90 kWh” between the cars. The energy capacity of cells can be measured in different ways so its hard to know exactly what 60 Ah or 95 kWh means unless you know under what conditions it has been measured. Neither Audi or Jaguar has not released that level of detail.

Using that energy, the e-tron has a WLTP estimate of 249 miles. WLTP is the new European test cycle that replaces the less realistic NEDC which Audi previous used to estimate an e-tron range of about 310 miles. Jaguar says the I-PACE has a WLTP of 298 miles but has only an estimated EPA range of near 240 miles. The Chevrolet Bolt EV has a WLTP range of 236 miles and an EPA range of 238. Jaguar’s 298 mile WLTP estimate seems oddly high.

A closeup with an I-PACE battery module cover removed to show the 12 LG pouch cells inside.

We know that Korean conglomerate LG is making the I-PACE cells (as well as for the Chevrolet Bolt EV). Recent rumors have said that Audi is using either LG or Samsung SDI cells.

Dr. Danson Joseph, the leader of the I-PACE battery group, holds one of the car’s LG cells.

One difference that stands out is charging speed. Audi claims to charge noticeably faster from 0 to 80 percent in 30 minutes vs 0-80 percent in 40 to 45 minutes in the I-PACE. Audi seems to be saying that the e-tron can actually charge at a peak rate of about 150 kW. This is plausible due to the higher than usual battery pack voltage levels and because some “150 kW” chargers like the ABB Terra HP can output up to 375A. The I-PACE has a peak charging rate of close to 100 kW during the first 15 minutes of charging.

Audi’s VW group peer, Porsche, has claimed their Mission E car being brought to production in late 2019 will charge from 0 to 80 percent in 15 to 20 minutes. Porsche says their battery can charge so fast that they need to double the charging voltage up to around 800-volts. This implies that the Audi cells may be different from the ones being used by Jaguar.

See also: How does 800V charging work?

Another similarity between the packs is the thermal management. Both designs use a water-based liquid coolant (essentially identical to what is used in an internal combustion engine) and circulate it under the aluminum housing tray that holds the battery modules.

Although not shown in the illustration above, there is likely a thermal transfer pad between the modules and the housing tray like there is in the I-PACE.

An apparent thermal transfer pad is applied to the base of a prototype I-PACE battery pack. One of the 36 cell modules will later be installed above it. Although unstated in the Jaguar video, there is likely a liquid coolant tray underneath the pack.

After Elon Musk publicly announced that Tesla was open to allowing access to its Supercharger network under the right deal there were various rumors about whether this or that traditional auto maker was negotiating a deal with them. That speculation included Jaguar.

Although there may be business reasons to forego a deal with Tesla there is also a technical conflict. Both the I-PACE and e-tron packs reach about 450 volts when full but at least some of the Tesla Superchargers can only output up to 410 volts because that’s all Tesla’s packs have needed so far.

See also: Jaguar and Chevy have LG in common

Categories: Battery

Another interesting article. Thanks.

I have some pictures of the latest cells from LG Chem here – http://www.mykiasoulev.com/forum/viewtopic.php?f=14&t=565&p=8043#p8043

I think the Audi E-Tron is the 4th in the list.

LikeLiked by 1 person

Thanks! Actually, the power tabs offset from middle on cell number 3 looks more like the I-PACE cell physically to me. I really wish they would publish some basic specifications on the cells.

Have you seen a verifiable photo of a Kona EV cell?

LikeLike

No, not the separate individual cells, just the cells in the pack. I have info about the Kona battery pack and cells here – http://www.mykiasoulev.com/forum/viewtopic.php?f=14&t=662&p=8044#p8044

LikeLiked by 1 person

Excellent new information on the Kona EV.

You said you found 2 of the photo images online and you took the others at the event yourself. It looks like one of the images is from a YouTube video. Can you give me a link to the video? Where was the other online image from and which of the images is it?

I noticed that the official Kona EV website for the Norwegian sales market listed a different smaller battery capacity for a few weeks late last year. Originally it said the large pack was 62.4 and the small back was 39.2 kWh. Then around October, 2017 they corrected it to say the smaller pack was 42.7 kWh. That happens be exactly 2/3 of 64,2 kWh as if the smaller pack has 2 cells in a cell group instead of 3.

Now it just says 64 kWh and no longer mentions the smaller battery pack. It is at https://kona.no/spesifikasjoner/.

LikeLike

Jeff and others: a bit off topic … I’ve been following the EV industry for many years now, but this is mind-blowing (by Tony Seba):

LikeLiked by 1 person

Thanks, I will watch that. I think I have seen him speak at Stanford before but this presentation looks more recent.

LikeLike

1) The video above from 2017 is very informative. Below is one from this year.

I thought I knew the EV market pretty well (I have been driving EVs for six years now. Two Leafs, two MB B ED, one e-Golf, my family of three drivers, all leased), but Tony Seba’s work suggests I didn’t really understand what is going on, or what is about to happen.

I know very little about AI, but ….

AI and EVs may dramatically change the transportation world: AEV (autonomous EVs)

Suggestion: when you watch the video pause it often to view the slides carefully.

Mind blowing, even if he is half correct.

2) To get a better feel for AI, please see this AI documentary and the article of AlphaGo Zero

Documentary on AI:

http://doyoutrustthiscomputer.org/ (cost $4 to see film)

AlphaGo Zero. Check out the two videos in this article as well:

https://www.theguardian.com/science/2017/oct/18/its-able-to-create-knowledge-itself-google-unveils-ai-learns-all-on-its-own?CMP=share_btn_tw

LikeLike

The main thermal plate grid doesn’t look right. The grid concept appears OK – designed for single-pass, with the glycol supplied in a manifold on one side, which then flows through the flat plates in-parallel to the manifold on the other side to be returned.

But the illustration shows two manifold pipe connections on one manifold and none on the other (at least none visible).

The smaller grid for the double-stacked modules makes more sense. Only one pipe connection shown on one side. The other side is not visible, but I would assume it has the 2nd pipe connection.

Note that if it is single-pass, the modules on the supply-side manifold side will be slightly cooler than the manifolds on the return-side manifold side. But it is a simple, with a lot of short parallel flow paths which means a lot of glycol can flow, so maybe the delta T between supply and return isn’t too much and the cell temps remain relatively close throughout the pack.

LikeLiked by 1 person

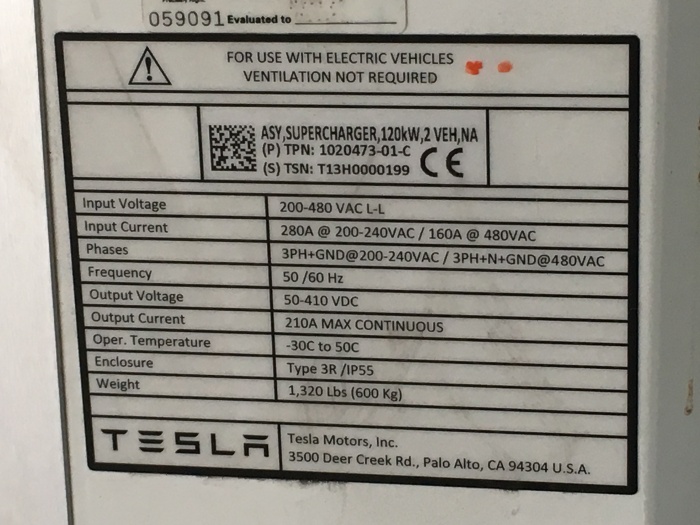

On the Tesla 2-vehicle SC – note that it is name plated “120 kW”. but then the nameplate data also says peak output DC volts is =410 volts & 210 A continuous. That only adds up to 86 kW max continuous output. At a busy SC with one SC charging two vehicles continuously, the effective per-vehicle charge rate will really take a hit.

How do the new 150 kW CCS (and higher) chargers stack up for continuous output?

LikeLike

That Supercharger is an older model, I suspect, but it’s the only one I had handy. I need to find a new Supercharger nameplate to photograph.

LikeLike

Final comment then back to work:)

Note the e-tron inter-module bussing is much cleaner than the iPace.

For the iPace, I just don’t get the logic of arranging the modules to require all those zig-zagging bus bars crossing over the module tops.

LikeLike

I’m supposing they arranged things that way due to geometrical space limitations but it’s hard to know.

LikeLike